Reprorubber® Thin Pour

Reprorubber® Thin Pour is a two component, addition cured, platinum catalyzed, hydrophobic vinyl polysiloxane. Its two components are poured into a container and mixed to obtain a uniform mixture. It may be used to reproduce surface characteristics. It is able to reproduce surfaces down to submicron particles or scratches. It is cured at room temperature. However, warmer temperatures accelerate the setting time and cooler temperatures slow the setting time.

Light Green

Further information on composition available on SDS.

Physical Properties Information

Available Products

Trial Size Kit

(#16116) Thin Pour 130ml trial kit - Purchase

Standard Size Kits

(#16135) Thin Pour 380ml kit - Purchase

(#16137) Case of 10 380ml kits - Purchase

Cartridge System Kits

(#16300) Thin Pour Quick Dispense Cartridge System kit complete - Purchase

(#16309) Combo Kit Quick Dispense Cartridge System kit - Purchase

Thin Pour Physical Properties

Determined at 23°C (72°F) (Tested according to ISO 4823)

- Base Paste

- Appearance - Homogenous blue-colored runny paste, Filling loading approximately 25% silicon dioxide.

- Catalyst Paste

- Appearance - Homogeneous, yellow-colored runny paste, filling loading approximately 25% silicon dioxide.

- Mixed Material

- Appearance - Homogenous green-colored runny paste.

- Mixing Time

- 30 seconds, larger masses may take up to 60 seconds

- Working time (prior to gellation) 4.0 - 4.5 minutes

- Setting Time

- 8 – 9 minutes. Varies with ambient temperature. Warmer temperatures accelerate the setting time. Cooler Temperatures slow the setting time.

- Compression Set (Recovery from deformation)

- 0.5%.

- Strain in Compression (A modified Modulus of Elasticity)

- 6 - 7%.

- Shore A30

- Dimensional Change

- After 24 hours - 0.50% Change (negative 0.50% change) this means it shrinks 0.50%

- After 7 days - 0.50% Change (negative 0.50% change) this means it shrinks 0.50%

- Tear Strength

- 200 psi

- Flash Point of the Polymers Used

- 130°C (266°F)

- Ignition Temperature of the Polymers Used

- 470°C (878°F)

- Fully set material may be autoclaved, but its dimensional stability may be compromised. If allowed to return to room temperature, should return to original shape.

- Disinfection

- Since material is hydrophobic, immersion in disinfectants is acceptable. The surface color may change due to the disinfectants used.

For Reprorubber® Thin Pour Users

Repro-Mix™ II Dispensing Gun System

A mixing and dispensing system that enables you to make quick and accurate reprorubber replicas, without manual mixing and fuss!

Repro-Mix™ II System consists of the following:

- 50ml dual barrel syringe with reusable end cap; easily filled by pouring contents of Reprorubber® into cartridge barrels.

- Disposable low cost Helix Mixing Nozzle Tips easily attach to and detach from dual barrel syringe.

- REPRO-MIX™ II Dispensing Gun.

Available Products

Repro-Mix™ II Kit

(#16300) Complete Repro-Mix™ II Kit - Purchase

Consisting of 1 each Repro-Mix™ II Dispensing Gun, 6 each 50ml prefilled Reprorubber Disposable Cartridges, 15 each Disposable Mixing Nozzles, deluxe fitted carrying case, and complete instructions for usage.

Replacement Items

(#16301) Reprorubber® Thin Pour (Green) 50ml Cartridge, 1 each - Purchase

(#16302) Reprorubber® Thin Pour (Green) 50ml Cartridges, 6 pack - Purchase

(#16311) Repro-Mix™ II Dispensing Gun (reusable) - Purchase

(#16313) Repro-Mix™ II Helix Mixing Nozzles, 15 Pack - Purchase

(#16316) Repro-Mix™ II Helix Mixing Nozzles, 100 Pack - Purchase

(#16314) Micro Injector Nozzle, Pack of 15 - Purchase

(#16315) Quick Dispense Cartridge System Fitted Case (without contents) - Purchase

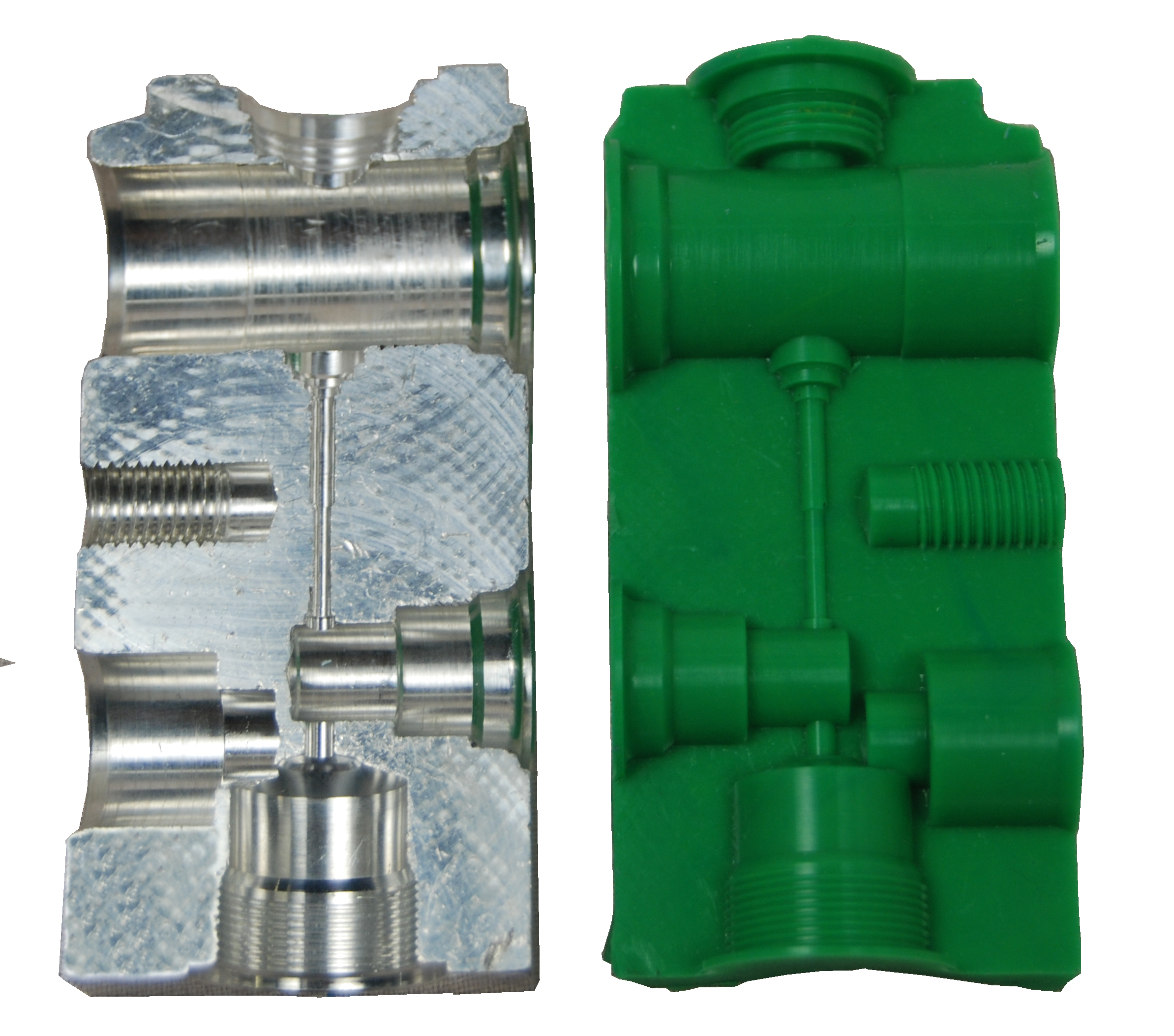

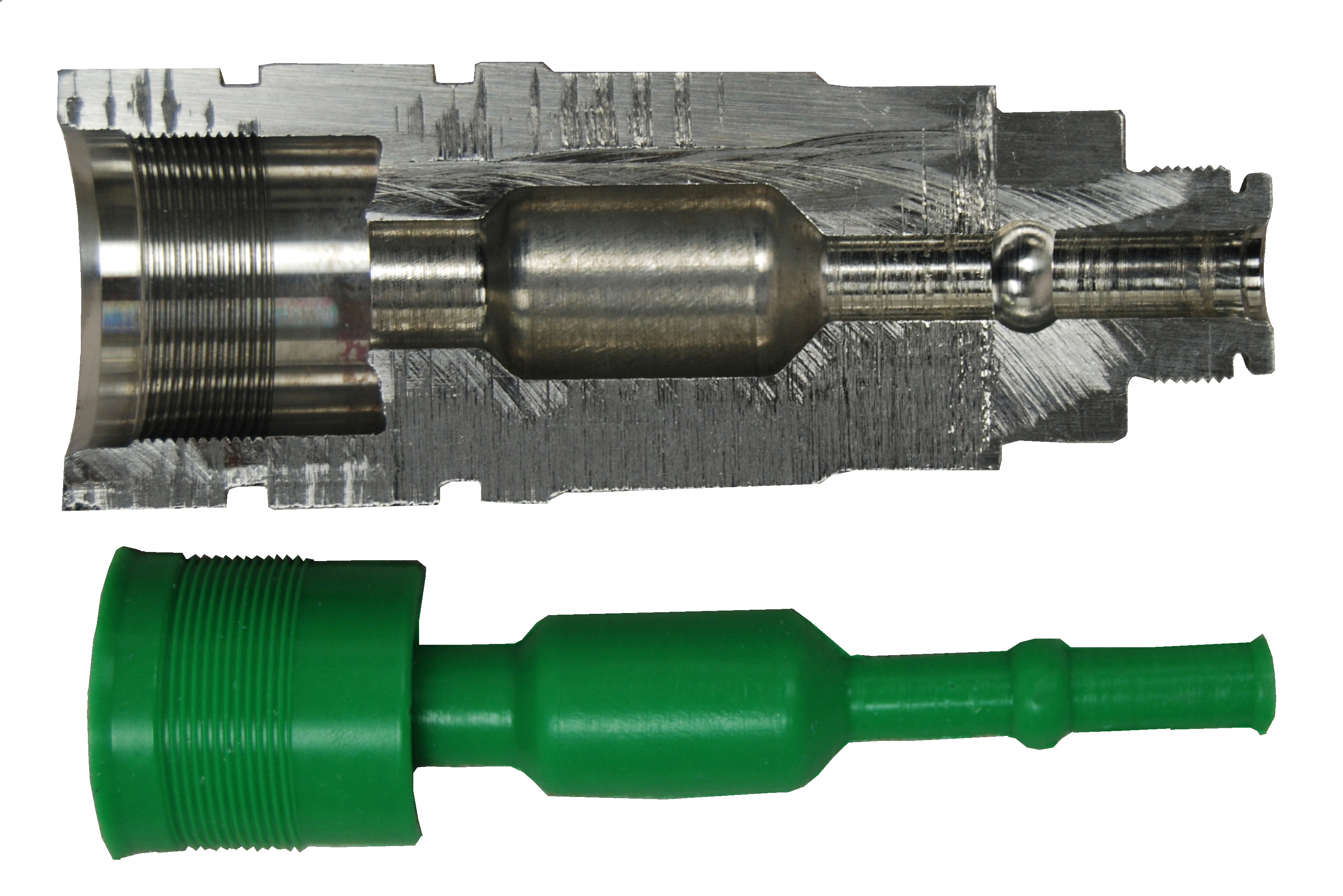

Applications

You can take impressions of:

- All Metals

- Non Metals

- Paper or Cardboard Items

- Ceramic and Glass items

Other Uses Include:

- Fixturing where semi-rigid structure is desired.

- Making joints where flexibility is required.

- Replica is easy to remove - even if there are under cuts or grooves.

- Cross-sectioning of replica is easily accomplished with a knife or razor.

- It can then be checked on an optical comparator or microscope.

- Surface finish replication is exact with excellent optical properties.

- Replicas are permanent - will not leach or ooze out nor outgas.

- Wood, Marble, etc.

- All Plastics

- Rubber

- Prototypes of rubber type components such as gaskets, washers, etc.

- As a mask for high temperature plasma spray of metallic coatings.

- No more 16 hour cure time as with RTV silicones

- More accurate than all other RTV compounds

- Reprorubber® Putty will withstand up to 600°F (or more).

- Reprorubber® copies can be recopied (copy from a “female mould” yields a male-shaped replica).